PPE, or personal protective equipment, covers a wide range of garments and face/body coverings as well as safety footwear, which are designed specifically for the functional benefit of protecting the wearer, increasing safety and reducing risk, for example from elements such as viruses and bacteria, harmful chemicals and gases.

Commonly used PPE includes eye and face protection (masks, shields), hand protection (gloves), body protection (gowns), respiratory protection and hearing protection. These are primarily textile or nonwoven based items and used regularly by medical professionals and healthcare personnel.

There are of course many other applications of PPE than the examples listed here, however, the Covid-19 pandemic focused a spotlight on the medical/surgical need for PPE and the associated testing standards we are about to cover.

The importance of PPE testing

There are stringent quality controls in place for medical equipment and PPE, and so testing is a crucial step in order to meet the relevant standards. James Heal instruments are suitable for testing some of these, which are outlined below along with the relevant specifications, standards and test methods.

1. Face Coverings

There are different types of protective face covering: Protective face masks and surgical face masks. Below are the main standards and test methods required for each.

Standard: EN 149:2001+A1:2009 - Respiratory protective devices

Protective masks are designed to protect against particles such as dust and various airborne viruses. These masks, unlike surgical masks, protect the wearer from inhaling infectious agents or pollutants in the form of aerosols, droplets, or small solid particles.

They're primarily made from polypropylene, polyester-rayon, glass and cellulose. Glass fibre is rarely used as it's known to cause skin irritation, and Polypropylene is used more frequently due to its hydrophobic nature and its capacity for wicking, which provides a dry and comfortable microclimate between the mask and face.

These masks can be used in domestic, industrial and healthcare applications.

What should the filter efficiency be?

EN 149 2001 defines three classes of filter efficiency for these masks:

- FFP1 - 80% filtering efficiency

- FFP2 - 94% filtering efficiency

- FFP3 - 99% filtering efficiency

Which class of efficiency is recommended for different types of use?

During the COVID-19 pandemic, the World Health Organization (WHO) recommended the minimum of an FFP2 mask for offering protection. The NHS stipulated FFP3 in high risk areas and FFP2 in lower risk areas.

In addition, masks are classified as single shift use only (marked NR on the product) or as re-usable e.g. more than one shift (marked R on the mask).

"These products must comply with the European Personal Protective Equipment (PPE) Regulation and be certified by a Notified Body and feature the CE marking. They are a Category III product under the PPE Regulation, so they must bear the CE Marking and a four-digit number identifying the Notified Body certifying it."

Standard EN 14683:2019 - Medical / Surgical Face Masks

Surgical / medical face masks are intended to limit the transmission of infective agents, and can also incorporate a microbial barrier that is designed to be effective in reducing the emission of infective agents from the nose and mouth of a carrier or a patient with clinical symptoms.

Contemporary surgical masks are usually composed of three nonwoven fabric layers - a cover web, a filter layer and a shell fabric and are intended to be a barrier to infection of others, though they do offer limited protection to the wearer. This is due to the filter layer between the cover web and shell fabric, which is a melt-blown nonwoven mat whose purpose is to deter hazardous aerosol particles, microorganisms and bodily fluids.

Surgical masks are classified into two main types:

- Type I - these masks should only be used by patients and other persons to reduce the risk of spread of infections particularly in epidemic or pandemic situations. Type I masks are not intended for use by healthcare professionals in an operating room or in other medical settings with similar requirements.

- Type II and Type IIR - these masks are principally intended for use by healthcare professionals in an operating room or other medical settings with similar requirements. Type II is further divided according to whether or not the mask is splash resistant. The R signifies splash resistance.

These products are certified under the European Medical Devices Regulation as a Class I device, so they must be CE marked based on the manufacturer's self-declaration unless they are supplied as sterile.

Types of test and which testing instruments to use

Both types of mask are subject to various tests to determine the efficacy of the end use. These include:

- Breathing resistance - inhalation and exhalation - apparatus also requires a "Sheffield dummy head" to which the mask is fitted and the air flow measured.

- Filter penetration using EN 13274-7

- Flammability using the ISO 6941 burner

- Attachment strength of valve (if fitted) - 10N - This can be tested using James Heal's Titan Universal Strength Tester; alternatively, a dead weight (1.019716kg) is sufficient, but ensure horizontal holding and non-return valve grip fixtures are used.

What about Community Face Coverings in the EU and UK?

Normally these face coverings are made with textile material which are not specifically designed for face masks. This means that all usual requirements in the EU and UK for textiles materials still apply. For example: mandatory requirements:

- Compliance with REACh and POP

- Toxic chemicals in packaging

- Labelling compliance

- Special requirements for children, e.g. small parts and chords

- Care label testing - shrinkage, appearance and colour fastness - if face covering is washable

- Fibre content (if applicable)

- Flammability (if applicable)

Recommended additional testing:

- Biocompatibility - ISO 10993-1

- Particle filtration efficiency (PFE) - EN 14683

- Breathability/Differential pressure (DP) - EN 14683 Annex C (using an Air Permeability Tester but operating in reverse mode)

- Strap attachment strength - using a James Heal Titan

- Elongation and strength of straps - using a James Heal Titan

- Mask dimensions and weight

- Apparel performance and appearance tests, e.g. colour fastness to perspiration and crocking

"These products must be labelled 'for non-medical use' and cannot make any claims that it prevents spread of infection (including Covid-19) nor any anti-microbial (antibacterial) or anti-viral claims."

In response to the Covid-19 pandemic, on 17th June 2020, CEN published the CEN Workshop Agreement CWA 17553 - Community face coverings - Guide to minimum requirements, methods of testing and use.

This was published after collaboration between many European countries (but not the UK) who had also published their own national standards for community face coverings.

Other European national standards are:

- France - AFNOR Spec S76-001 (see previous section)

- Belgium - NBN/DTD S65-001

- Spain - UNE 0065 (in conjunction with UNE 0064-1 and UNE 0064-2)

- Ireland - Swift 19

- Italy - UNI/PdR 90-1 and 90-2

- Hungary - MSZ 4209 and more...

These are mirror documents to CWA 17553 and published nationally in order to distribute the information quickly in the national language.

"Community face coverings do not fall within the meaning of a medical device under Directive 93/42/CEE or Regulation EU/2017/745 nor as PPE within Regulation EU/2016/425."

CWA 17553 specifies the minimum requirements for reusable or disposable community face coverings intended for the general public. In addition to test methods for face coverings, it also specifies requirements for design, performance, packaging, marking and information for use.

"If the face covering is classified as washable then the minimum washing temperature is 60°C (140°F). It should be washed using standard detergent and fabric softener should not be used. They should not be dry cleaned due to the possibility of residual chemicals which are hazardous to health."

Filtration efficiency

Using particle of 3um, you have a choice of four test methods:

- EN 13274-7

- EN 14683 Annex B

- EN ISO 16890-2 or

- EN ISO 21083

Breathability

This can be assessed with a choice of three test methods:

- EN 14683 Annex C - DP of the material ≤ 70 Pa/cm2 which correlates to approx. 80 l/s/m2 for a vacuum pressure of 100 Pa;

- EN 13274-3 - Inhalation resistance of 2.4 mbar and exhalation resistance of 3 mbar; or

- EN ISO 9237 - the air permeability shall be ≥ 96 l/s/m2 for a vacuum pressure of 100 Pa.

Filtration efficiency and breathability can be assessed using instruments such as James Heal's Wascator and AccuDry, and should be maintained after the number of your specified number of washing cycles, which should be a minimum of 5 washing cycles.

2. Protective Clothing

These are the main specifications for protective clothing:

- EN 13795-1:2019 - Surgical clothing and drapes. Requirements and test methods. Surgical drapes and gowns

- EN 13795-2:2019 - Surgical clothing and drapes. Clean air suits

- ASTM 2407-06 (2013) - Standard Specification for Surgical Gowns Intended for Use in Healthcare Facilities

For the above specifications, the following Instruments and Standards are relevant:

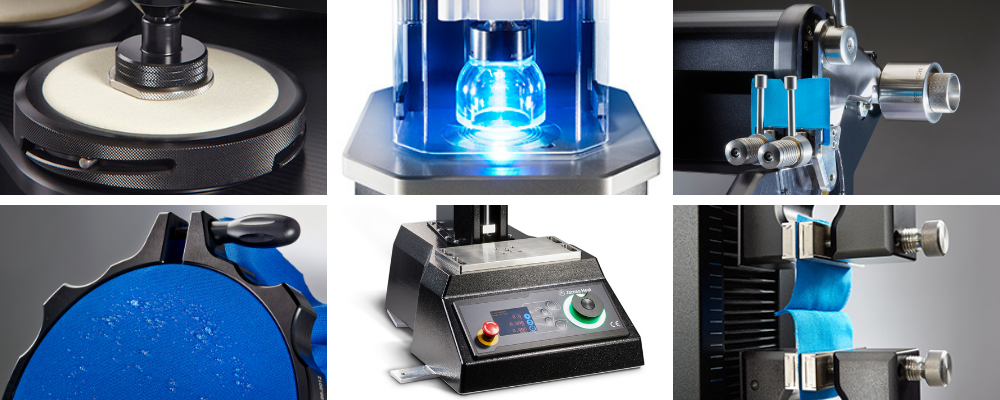

Martindale

EN 530 for Abrasion Resistance

ElmaTear

ASTM D1424 for Tear Resistance ISO 13937-1 for Tear Resistance

TruBurst

EN 13938-2 for Bursting Strength

Spray Rating Tester

ISO 4920 for Water Resistance

GB/T 4745 for Water Resistance

AATCC 22 for Water Resistance

Titan

ISO 13934-1 for Breaking Strength and Elongation

GB/T 3923.1 for Breaking Strength and Elongation

ISO 9073.4 for Tear Strength

EN 863 for Puncture Resistance

ISO 13935-2 for Seam Strength

EN 29073-3 for Tensile and Elongation

ASTM D5034 for Tensile Strength

ASTM D1682 for Tensile Strength

ASTM D1683 for Seam Slippage and Strength

ASTM D5587(woven) for Tear Resistance

ASTM D5587 (nonwoven) for Tear Resistance

ASTM D751 for Seam Strength and Puncture Resistance

QuickTest

QuickTest is suitable for testing the integrity of Personal Protective Equipment, like the masks pictured or the glide force of syringes. There are several possible applications for this instrument, please contact us for more information.

Other European standards for protective clothing, in this context include:

Standard EN 14126:2003 - Performance requirements and tests methods for protective clothing against infective agents This is a harmonised standard for the PPE Directive 89/686/EEC and the PPE Regulation (EU) 2016/425), and can be combined with other garment standards listed below to demonstrate compliance with the PPE Directive or Regulation.

"This standard is used to demonstrate the performance of protective garments against infective agents. This is not a ‘stand-alone’ standard and needs to be combined with standards for Type 1, 2, 3, 4, 5 and/or 6 protective garments, as listed in Clause 4.3, Table 5."

Types 1, 2 and 5 protective garments are required to be of the 'full body' type. Type 3, 4 and 6 protective garment standards include partial body 'PB' garments covering only a part of the body.

EN 14126:2003 is combined with one or more of:

- EN 943-1:2015 Performance requirements for Type 1 (gas-tight) protective suits.

- EN 943-2:2002 Performance requirements for Type 1 (gas-tight) protective suits for emergency teams (ET)

- EN 943-1:2002 Performance requirements for ventilated Type 2 (non-gas-tight) protective suits (Withdrawn)

- EN 14605:2005+A1:2009 Performance requirements for clothing with liquid-tight (Type 3) or spray-tight (Type 4) connections, including partial protection (Types PB [3] and PB [4]). EN ISO 13982-1:2004+A1:2010 Performance requirements for protective clothing providing protection against airborne solid particulates (Type 5)

- EN 13034:2005+A1:2009 Performance requirements for protective clothing offering limited protective performance against liquid chemicals (Type 6), including partial protection (Type PB [6])

- ISO 16602:2007+A1:2012 Performance requirements for protective clothing (Types 1 to 6)

Test methods and testing instruments

The following tests are performed in addition the tests identified in EN 14126, with the recommended test instruments to use to perform each test (where available): Using James Heal's Martindale

- Abrasion resistance EN 530 method 2 - Minimum Class 1

Using Schildknecht flexing:

- Flex cracking resistance ISO 7854 method B - Minimum Class 1

- Flex cracking resistance at -30°C ISO 7854 method B - Minimum Class 1 (Optional)

Using James Heal's Titan

- Tear resistance (trapezoidal test specimen) ISO 9073-4 - Minimum Class 1 - Titan with T27 jaws

- Tensile strength ISO 13934-1 - Minimum Class 1 - Titan with T27 jaws

- Seam strength ISO 13935-2 - Minimum Class 1 Titan with T27 jaws

- Puncture resistance EN 863 - Minimum Class 1 Titan with T27 jaws

- EN 455-2:2015 Medical gloves for single use. Requirements and testing for physical properties - Titan with Extensometer, Eccentric Roller Grips (ERG2)

- EN 29073-3:1992 Methods of tests for Nonwovens - Part 3: Determination of tensile strength and elongation - Titan with T27 jaws

Final thoughts

Following the Coronavirus pandemic, personal protective equipment (PPE) continues to see high demand on a global scale, as regions have seen the relaxation of restrictions.

This situation has only further highlighted the importance of Personal Protective Equipment's (PPE) efficacy to protect everyone - especially the vulnerable and key health workers - from contagions in the environment. Testing is therefore crucial to ensure that garments and masks are providing the protection advertised to the wearer and providing support in limiting the spread of infection.