In this installment of our Your Questions Answered series, we explore the subject of Burst Strength Testing.

We are often asked about this type of testing, so we have compiled some of the most frequently asked questions and answers as a resource to help with understanding. The key topics are:

Is the instrument used to test Tetra Pak packaging the same for other juice and milk packaging?

Answer

Packaging and their coatings can differ hugely, so you would need to refer to the standard you are wanting to test to & see what equipment is specified.

Packaging and their coatings can differ hugely, so you would need to refer to the standard you are wanting to test to & see what equipment is specified.

We have a type of packaging that has different layers of paper, board and aluminium foil. Does TruBurst cover this?

Answer

We have tested films and aluminum foils for pharmaceutical packaging using TruBurst in the past. If the layers are laminated then it may be possible to use different burst detection settings to detect when the weaker layer has failed.

We have tested films and aluminum foils for pharmaceutical packaging using TruBurst in the past. If the layers are laminated then it may be possible to use different burst detection settings to detect when the weaker layer has failed.

For legging products, what are the benefit(s) using the ball burst test method (ASTM D6797)?

Answer

For stretch fabrics, the diaphragm method is limited by the height of the test dome (bell). When using the ball burst method, the length travelled of the ball is usually much greater than the height of the dome allowing the fabric to be tested to burst, rather than reaching the maximum capacity of the dome. Results from D3786 and D6797 are NOT comparable.

For stretch fabrics, the diaphragm method is limited by the height of the test dome (bell). When using the ball burst method, the length travelled of the ball is usually much greater than the height of the dome allowing the fabric to be tested to burst, rather than reaching the maximum capacity of the dome. Results from D3786 and D6797 are NOT comparable.

For ASTM D3786, what material is the diaphragm actually made of? Is there designated diaphragm supplier(s) which the lab should purchase from?

Answer

Our diaphragms are made of natural rubber. Page 14 of the Operators Guide lists the different diaphragms we offer.

Bursting Strength Test Materials - James Heal Bursting strength tester (james-heal.co.uk)

Our diaphragms are made of natural rubber. Page 14 of the Operators Guide lists the different diaphragms we offer.

Bursting Strength Test Materials - James Heal Bursting strength tester (james-heal.co.uk)

Regarding the pass/fail requirements, for example: Pass Requirement 45 PSI The Bursting results that we found is 20 PSI. The specimen hadn’t burst. In this case are the results a pass or fail?

Answer

This depends what standard you are testing to. In some standards they advise to use a smaller or bigger dome. Some standards make provision of a sample not bursting. For example in ASTM D3786, it states: If the fabric does not burst, the report should state the maximum bursting pressure of the instrument and that the sample had not burst at that pressure.

This depends what standard you are testing to. In some standards they advise to use a smaller or bigger dome. Some standards make provision of a sample not bursting. For example in ASTM D3786, it states: If the fabric does not burst, the report should state the maximum bursting pressure of the instrument and that the sample had not burst at that pressure.

We have a hydraulic tester to apply ASTM D3786. Is there any limit to use it for knitted stretch fabrics? Would it be necessary to extend the fabric to remove some of the stretch, and is there any standard for this?

Answer

You would need to look into standards specific to hydraulic instruments. Our TruBurst is pneumatic, and we are not aware of any standards.

You would need to look into standards specific to hydraulic instruments. Our TruBurst is pneumatic, and we are not aware of any standards.

What is the recommended dome for testing paper?

Answer

The dome we recommend for paper is the 7.79cm2 size. Always refer to the standard you are using to ensuring that the instrument you are using is appropriate for the method.

The dome we recommend for paper is the 7.79cm2 size. Always refer to the standard you are using to ensuring that the instrument you are using is appropriate for the method.

In the case of fabric with elastane, which is the right way to put the sample for burst testing?

Answer

Insert the specimen between the top & bottom clamp ensuring that the specimen is free from creases and folds. This is the same method as non-stretch fabrics. The small dome would be used with stretch fabrics.

Insert the specimen between the top & bottom clamp ensuring that the specimen is free from creases and folds. This is the same method as non-stretch fabrics. The small dome would be used with stretch fabrics.

Are there noticeable differences in test results when testing is performed using hydraulic and pneumatic systems?

Answer

There is no significant difference in the bursting strength results achieved using pneumatic or hydraulic burst testers, for pressures up to 800kPa. This pressure range covers the majority of performance levels expected for general apparel (see ISO 13938-2). Some hydraulic burst testers include pressures exceeding 800kPa.

There is no significant difference in the bursting strength results achieved using pneumatic or hydraulic burst testers, for pressures up to 800kPa. This pressure range covers the majority of performance levels expected for general apparel (see ISO 13938-2). Some hydraulic burst testers include pressures exceeding 800kPa.

What is the required pressure for the bursting machine?

Answer

Maximum pressure: 10 bar (145psi) regulated

Minimum pressure: 6 bar.

The use of an air compressor expands the upper limit of available pressure from typical factory airlines to 1000kPa/145psi and are supplied with a filter and regulator.

Maximum pressure: 10 bar (145psi) regulated

Minimum pressure: 6 bar.

The use of an air compressor expands the upper limit of available pressure from typical factory airlines to 1000kPa/145psi and are supplied with a filter and regulator.

In which direction the sample must have tension, all directions or only in courses?

Answer

When testing is performed in TruBurst, the whole fabric is stretched multiaxial.

When testing is performed in TruBurst, the whole fabric is stretched multiaxial.

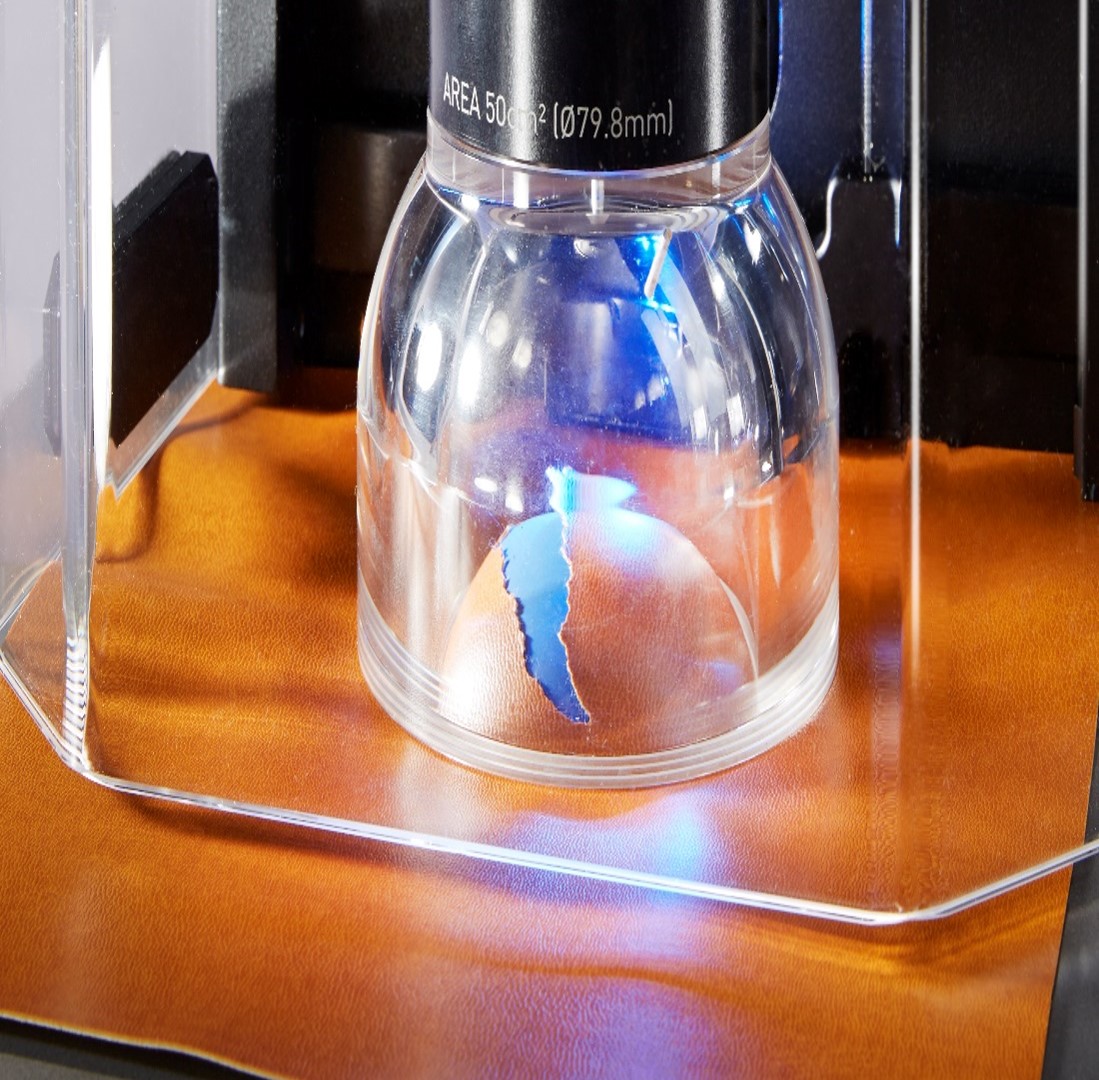

TruBurst

Burst Strength Tester

Pneumatic Bursting Strength Tester with TestWise™ software and a range of bursting strength and fatigue tests suitable for knitted textiles, medical textiles, nonwovens and plastics.