Testing across a broad spectrum of applications

There are numerous test methods used in order to establish nonwoven characteristics and determine their end-use applications: such as advanced wound care applications, or construction applications, medical devices, life sciences or industrial uses.

Some of the most common test types for nonwovens include:

- Absorbency

- Bursting Strength

- Air Permeability

- Moisture Permeability (water vapour transmission)

- Elongation

- Tear Strength

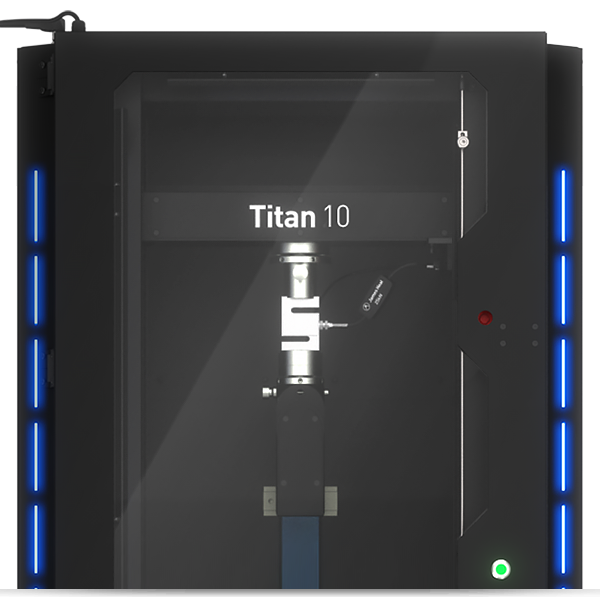

Accurate, reliable, repeatable results - every time

Testing both the product, and process performance of your nonwoven materials helps to identify and controlling key physical characteristics within acceptable ranges - to provide quality assurance, solve problems, and enable innovation through continuous improvement.

Create confidence in your brand

Nonwoven manufacturers need to find ways to accurately replicate the conditions their products are put through in the real world.

James Heal instruments enable you to carry out the necessary tests on your outdoor clothing and materials to validate claims and ensure intended performance, create consumer confidence and loyalty in your brand.

Since 1872 we've been on a mission to improve every aspect of materials testing, so our customers can achieve consistent and accurate results, every time. Our new Performance Testing Range has been designed for testing performance wear and technical textiles.